PT. Gunung Raja Paksi Tbk

Fortise & Fortise+

ON

STRENGTH

STRENGTH AND

SUSTAINABILITY

Reliable and cost-efficient for general structural applications.

Enhanced strength and durability for demanding use, with long-term savings on materials and maintenance.

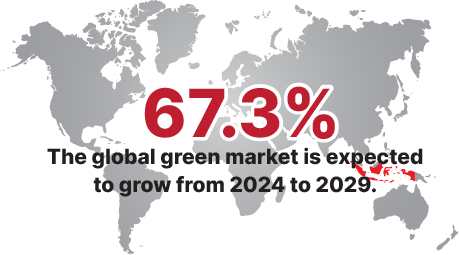

While blast furnace technology, dependent on coal and coke, remains common in Indonesia, the transition to cleaner, more efficient production methods is becoming increasingly essential.

For the national steel industry, emissions reductions are being implemented step by step, considering several factors such as government regulations/policies, industry competitiveness, existing technology, availability of Net Zero Emission (NZE).

Source : IISIA.

PRODUCT RANGE

Steel Plate

Our Steel Plate comes with a variety of standards and sizes that can be tailored to your needs.

FORTISE

Key Specification

ASTM A-285 / ASME A-285, ASTEM A-36 / ASME A-36, ASTM A-573 / ASME SA-573, ASTM A-131, ASTM A-709 / ASME SA 709, JISG 3101, JIS G 3101, EN 1002502:2004, EN 10025-3:2004, DIN 17100 (1980), AS/NZS 3678 ACRS Certificate No. 171202, BS 4360, BS 4360.

BKI, DNV, LR, ASTM A-131 (Ship Building)

Grade

SS-400, SM 400 A, SM 400 B, SM 400 C, S 235 JR, S 235 JO, S 235 J2, S 275 JR, S 275 JO, S275 J2, S 275 N, S 275 NL, ST 37.2, ST 44.2 etc.

A, B, D, E (Ship Building)

FORTISE+

Key Specification Yield Strength (± 400–500)

ASTM A-285, JIS G 3106, JIS G 3106, AS 3678 (2016), ASTM A 572, JISG 3101, JIS G 3106, EN 10025-4:2004, EN 10025-4:2004 etc.

BKI, DNV, LR, ASTM A-131 (Ship Building)

Grade

SM 490 YA, SM 490 YB, SM 520 B, SM 520 C, 400, 60, 65, SS-540, SM 570, S 420 M, S 420 ML, S 460 M, S 460 ML, etc.

AH32, EH32, DH 32, AH 36, EH 36, DH 36 (Ship Building)

Coil Plate

GRP uses equalizing process to produce highest standard of coil plate.

»» Features: Structural Steel

FORTISE

Key Specification

ASTM A36 / ASME SA36, ASTM A283 / ASME SA283, ASTM A285 / ASME SA285, JISG 3101, AS 1594, JIS G 3101 EN 1002502:2004, DIN 17100 (1980), etc.

Tingkatan/Grade

SS-400, HA 250, HU 250, SM 400 A, SM 400 B, SM 400 C, S 235 JR, S 235 JO, S 235 J2, S 275 JR, S 275 JO. S275 J2.

FORTISE+

Key Specification

ASTM A 572 / ASME SA 572, ASTM A 573 / ASME SA 573, JISG 3101, JIS G 3106, etc.

Grade

50, 55, 60, 70, SS-490, SM 490 A, SM 490 B. SM 490 C, SM 490 YA, SM 490 YB, SM 520 B, SM 520 C, etc.

»» Features: Pressure Vessel Steel

(Yield Strength >300 Mpa)

Key Specification

JISG 3101, ASTM A537/ASME SA537, EN 10028-2.

Grade

55, 60, 65, 70, SG 255, SG 295, CLASS 1, P265 GH, P295 GH

Welded Beam

Tailored Strength for Every Project.

For general applications and projects requiring mild steel, our welded beams can be fabricated using FORTISE grade materials.

This ensures reliable performance for standard construction needs.When your project demands high strength and an advanced commitment to sustainability, our welded beams can be manufactured with FORTISE+.

Customization and Flexibility: Tailored to specific project needs in terms of size, shape, and length, perfect for non-standard designs.

Suitable for Complex Structures: Ideal for intricate geometries or specific load-bearing requirements, such as bridges, industrial buildings, and heavy-duty equipment.

High Strength and Durability:Properly welded beams deliver excellent strength and durability, capable of handling significant loads and stresses.

To see the others product, click here.

MECHANICAL PROPERTIES

| Property | FORTISE | FORTISE+ |

|---|---|---|

| Yield Strength (Mpa) min | 235 | 345 |

| Tensile Strength (Mpa) | 400–550 | 485–600 |

| Elongation (%) min | 17 | 15 |

| Hardness (HV 10) max | 210 | 210 |

| Impact (Joule) min (+20 up to –40) |

27 | 34 |

| Weather resistant | – | If the grade comply with specification of weather resistant grades. The steel should be have chemical content Cu (0,15–0,50%), Cr (0,35–1,05) |

Carbon Emission (Include % Scrap)

The differentiation between FORTISE and FORTISE+ supports Indonesia’s broader decarbonization efforts in several ways:

APPLICATIONS

FORTISE targets general structural applications. It is suitable for:

→ Distributors and Fabricator make a really good customers/target here.

FORTISE+, on the other hand, is engineered for demanding,high-spec applications, such as:

→ Consultant, Data center project owner, multinational project (oil and gas, etc) should be this segments target.

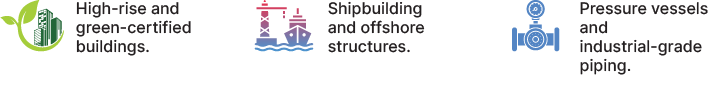

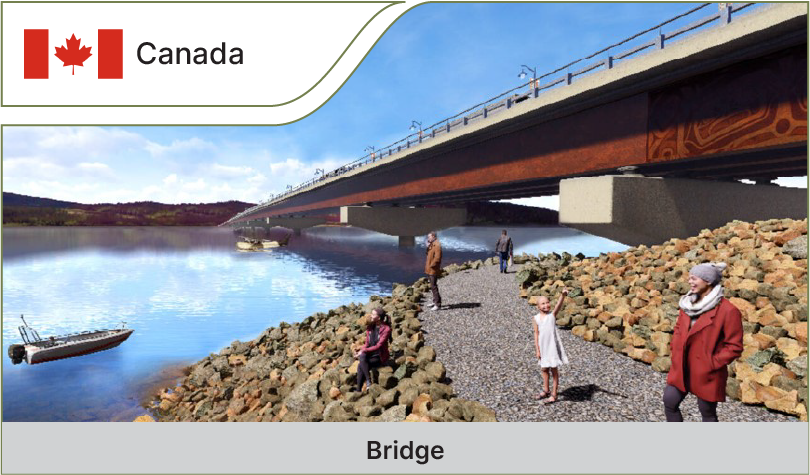

PROJECT PORTFOLIO

GRP supports major local and international projects with reliable and high quality solutions tailored to project need.

DELIVERING VALUE AND SUSTAINABILITY THROUGH FORTISE AND FORTISE+

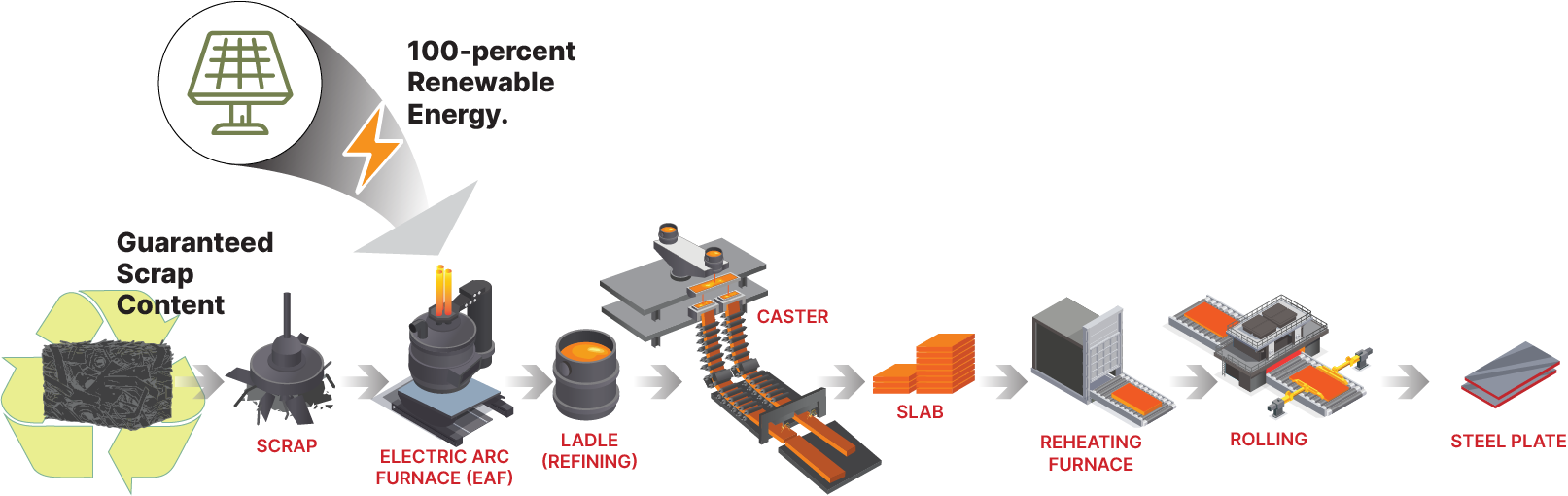

FORTISE and FORTISE+ are produced using Electric Arc Furnace (EAF) technology—enabling a more efficient and environmentally responsible steelmaking process aligned with global sustainability standards.

FORTISE+ offers enhanced circularity by utilizing approximately 70% scrap input, contributing to the reduction of embodied carbon and supporting low-emission development goals.

Complementing these efforts, GRP operates a Rooftop Solar Panel system with an installed capacity of 9.3-megawatt peak (MWp), positioning it among the largest rooftop installations in West Java and reinforcing our commitment to responsible energy use.

Understanding Low Carbon, click here.

BEYOND CARBON REDUCTIONS

At GRP, sustainability goes beyond emissions. GRP integrates environmental responsibility across its operations — offering steel products that meet leading national and international benchmarks for eco-efficiency. GRP’s commitment is recognized through the following certifications:

• Environmental Product Declaration (EPD)

GRP’s steel products are backed by verified EPDs, providing transparent, third-party data on carbon footprint and life cycle impact. This will help our customers to meet with green building and procurement standards.

• Green Label Indonesia

Certified by the Green Product Council Indonesia, GRP’s products are acknowledged for their lower environmental impact and support for sustainable construction.

• Standar Industri Hijau (SIH)

As part of Indonesia’s standard for responsible industrial operations, this certification from the Ministry of Industry affirms GRP’s continuous efforts in optimizing energy use, material efficiency, and environmentally sound production.

These achievements reflect GRP’s role in enabling cleaner, more sustainable development through certified steel solutions.